Advances in Lightweight Materials for Car Parts

11xplay online id, anna reddy book, golden7777.com admin:Advances in Lightweight Materials for Car Parts

Cars have come a long way over the years, with advancements in technology revolutionizing the way vehicles are designed and built. One significant development in the automotive industry is the shift towards using lightweight materials for car parts. Lightweight materials offer several advantages, including improved fuel efficiency, better performance, and reduced environmental impact. In this article, we will explore some of the latest innovations in lightweight materials for car parts and how they are changing the way we think about building vehicles.

The demand for lightweight materials in the automotive industry has been steadily increasing due to the need for more fuel-efficient vehicles. Lightweight materials help to reduce the overall weight of a car, which in turn improves fuel efficiency. This is because lighter cars require less energy to accelerate and maintain speed, resulting in better gas mileage. Additionally, lightweight materials can also improve the performance of a vehicle by enhancing its handling and agility.

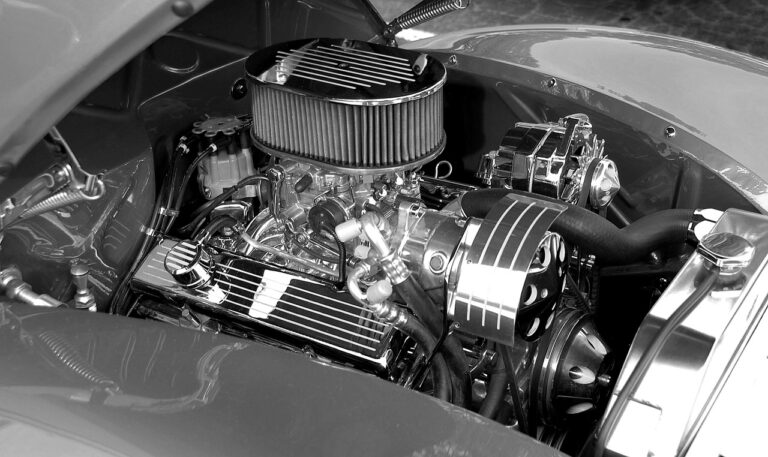

One of the most common lightweight materials used in car parts is aluminum. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal choice for various components, including body panels, engine blocks, and wheels. Aluminum is also recyclable, making it a more sustainable option compared to traditional materials like steel. Automakers have been increasingly incorporating aluminum into their vehicles to help reduce weight and improve fuel efficiency.

Another lightweight material that is gaining popularity in the automotive industry is carbon fiber. Carbon fiber is a high-strength, lightweight material that is used in various components, such as body panels, hoods, and interior trim. Carbon fiber offers exceptional strength-to-weight ratio, making it an excellent choice for improving the performance of a vehicle. While carbon fiber is more expensive than traditional materials, its benefits in terms of weight reduction and performance make it a worthwhile investment for many automakers.

In addition to aluminum and carbon fiber, automakers are also exploring other lightweight materials, such as magnesium, titanium, and composites. These materials offer unique properties that can help improve the overall performance and efficiency of vehicles. For example, magnesium is lighter than aluminum and offers excellent damping characteristics, making it a suitable material for components that require high strength and vibration resistance. Titanium is another lightweight material that is known for its strength and corrosion resistance, making it a popular choice for high-performance vehicles.

Composite materials, which are made up of two or more different materials, are also being used in car parts to reduce weight and improve performance. Composites offer a combination of properties that are not available in individual materials, making them an attractive option for automakers. For example, carbon fiber reinforced plastics (CFRP) are commonly used in automotive components like body panels and chassis parts, offering a lightweight and rigid alternative to traditional materials.

Overall, the use of lightweight materials in car parts is revolutionizing the automotive industry, leading to more fuel-efficient, high-performance vehicles. As automakers continue to innovate and develop new materials, we can expect to see even more advancements in lightweight materials for car parts in the future. By incorporating these innovative materials into their vehicles, automakers can create vehicles that are not only more efficient and environmentally friendly but also offer superior performance and driving experience.

—

Advances in Lightweight Materials for Car Parts

Heading 1: Aluminum

Heading 2: Carbon Fiber

Heading 3: Other Lightweight Materials

Heading 4: Composite Materials

Heading 5: Future Innovations

Heading 6: Benefits of Lightweight Materials

—

FAQs

Q: Are lightweight materials more expensive than traditional materials?

A: Lightweight materials like carbon fiber can be more expensive than traditional materials like steel or aluminum. However, the benefits in terms of weight reduction and performance often outweigh the initial cost.

Q: Do lightweight materials affect the safety of a vehicle?

A: Lightweight materials are designed to be just as safe as traditional materials. Automakers conduct extensive testing to ensure that vehicles made with lightweight materials meet safety standards and provide adequate protection for occupants.

Q: How do lightweight materials impact the environment?

A: Lightweight materials can help improve fuel efficiency and reduce emissions, making vehicles more environmentally friendly. Additionally, materials like aluminum and carbon fiber are recyclable, further reducing their environmental impact.

Q: Can lightweight materials be repaired in case of damage?

A: Lightweight materials like carbon fiber can be repaired in the event of damage, although the process may be more involved compared to traditional materials. Automakers and repair shops have the necessary tools and expertise to repair lightweight materials effectively.

Q: Will lightweight materials become more prevalent in future car models?

A: Yes, as automakers continue to prioritize fuel efficiency and performance, lightweight materials are expected to become more common in future car models. Advancements in material science and manufacturing processes will likely lead to even more innovations in lightweight materials for car parts.

Q: Are lightweight materials suitable for all types of vehicles?

A: Lightweight materials are suitable for various types of vehicles, including passenger cars, trucks, and even electric vehicles. These materials offer benefits in terms of weight reduction, performance, and efficiency, making them a versatile choice for automakers looking to improve their vehicles.

Remember, when it comes to lightweight materials for car parts, the future looks bright. Automakers are constantly pushing the boundaries of what is possible, as they strive to create vehicles that are not only more fuel-efficient but also offer superior performance and driving experience. By incorporating lightweight materials into their vehicles, automakers are leading the way towards a more sustainable and efficient automotive industry.